WINDA Cases

WINDA seamlessly integrates with top-tier industrial hardware and software providers across the midstream ecosystem—ensuring rapid deployment, scalable interoperability, and maximum return on your existing technology investments.

Beijing Sewer Corrosion Monitoring: Fusing Digital Twin and Predictive AI for Urban Infrastructure Resilience

Real-time sensing, AI forecasting, and cathodic protection optimization—engineered to predict, prevent, and prescribe against underground corrosion.

Learn More

AI-Powered Automation Slashes Downtime and Boosts Oil Production

Predictive analytics and IoT reduce pump failures by over 20%, increase production up to 10%, and cut labor costs by 40% in extreme oilfield environments.

Learn More

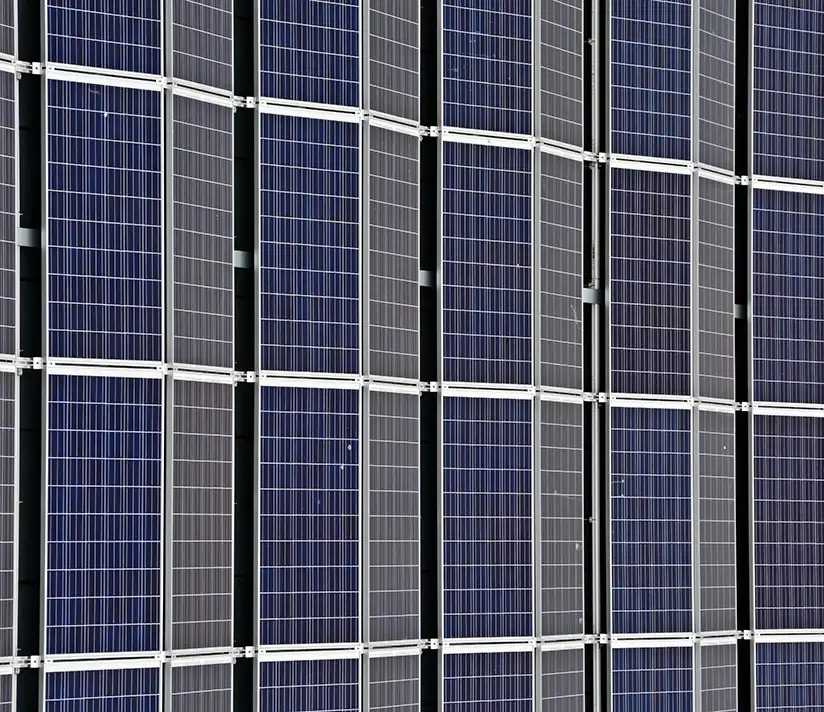

Solar-Powered AI Delivers Sustainable, Reliable Energy for Remote Oilfields

Cutting diesel dependency by up to 90%, reducing annual emissions by 100+ tons, and ensuring uninterrupted operations through intelligent solar-storage integration

Learn More

AI Predictive Analytics Halves Downtime Across Global Operations

Transforming maintenance from reactive to predictive—achieving 50% fewer breakdowns, faster diagnostics, and enterprise-wide visibility into asset health.

Learn More

AI Valve Diagnostics Prevent Costly Shutdowns and Extend Equipment Life

Reducing unnecessary maintenance, increasing safety, and improving uptime by proactively identifying valve issues—before they impact production.

Learn More

Data-Driven Analytics Cuts Compressor Downtime by Nearly 50%

Transitioning maintenance from reactive to proactive with predictive diagnostics—optimizing compressor efficiency, reducing emergency repairs, and maximizing productivity.

Learn More

Improving Well Availability and Productivity Through AI

A large upstream operator was grappling with inconsistent well performance and suboptimal production in key fields. The company aimed to leverage AI techniques to enhance well availability, streamline interventions, and boost overall productivity.

Learn More

Predictive Well Analytics Maximizes Uptime and Boosts Production

Leveraging real-time insights and proactive alerts to reduce downtime, streamline maintenance, and unlock sustained productivity across oilfield operations.

Learn More

Smart Inventory Forecasting Reduces Costs and Prevents Downtime

Accurately predicting demand, automating reorders, and unlocking working capital by right-sizing inventory levels—ensuring availability without overstocking.

Learn More

Real-Time Quality Analytics Boost Yield and Reduce Defects

Instant visibility into product quality enables rapid adjustments, reduces waste, and ensures consistently superior outputs batch after batch.

Learn More

Leading the Energy Transition with Digital Precision and Emissions Efficiency

Aramco leverages AI, low-carbon operations, and global R&D to deliver energy security and sustainability at scale.

Learn More